Marking & Traceablility

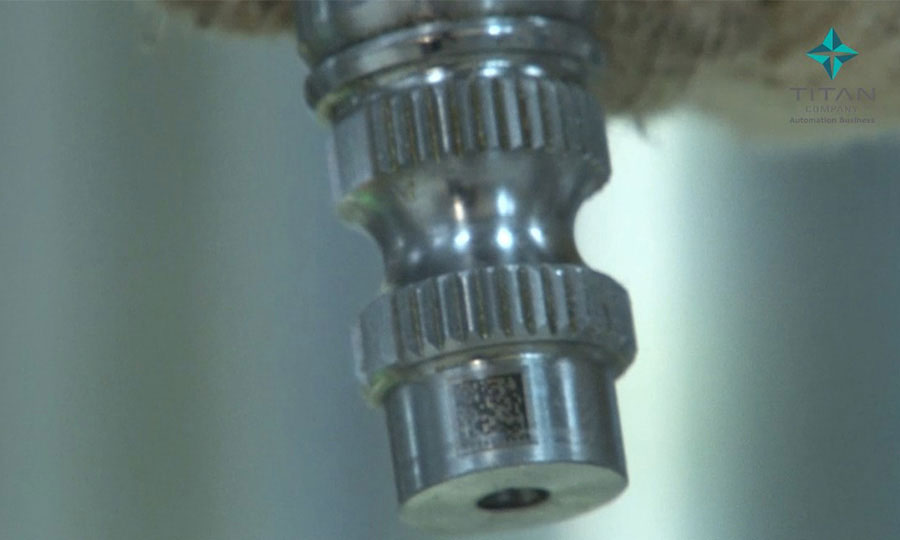

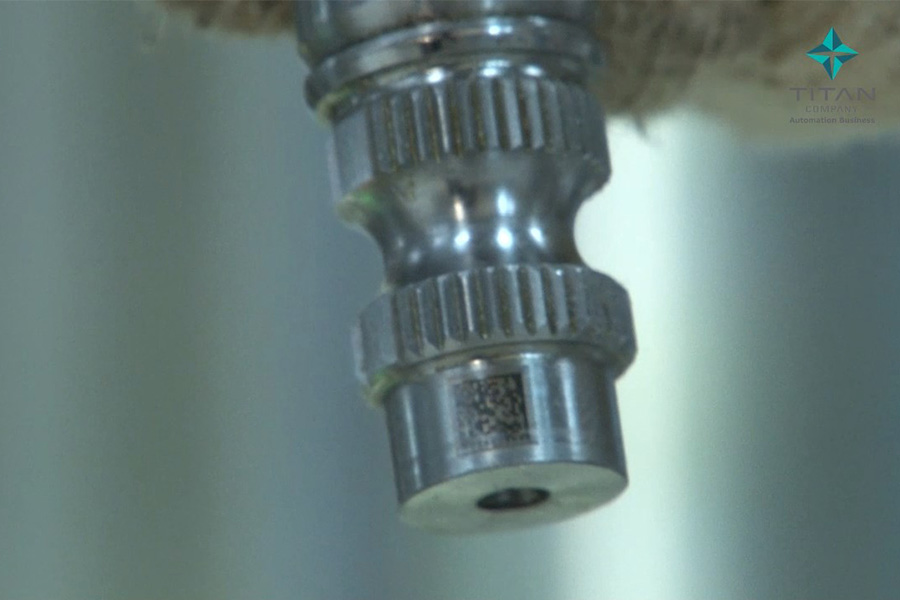

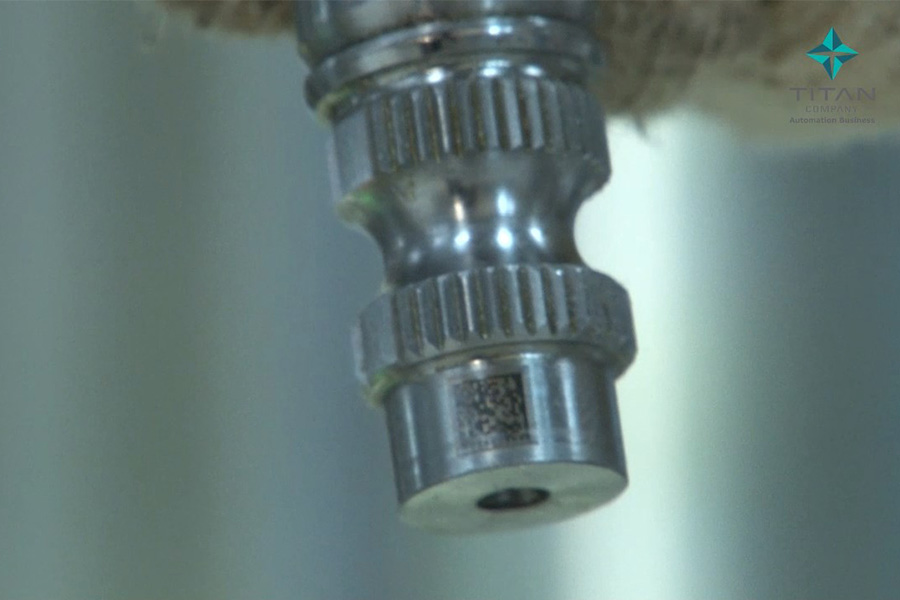

Marking/Printing operation plays a key role in the Manufacturing process since it is associated with traceability of the product for its complete lifetime. Quality marking/printing operation requires deeper understanding of several factors of the product such as Material, Part Function, Geometry, Surface Finish, Coating Thickness etc.

As part of the complete turnkey solution, we have executed various projects. The different methods include

- Inkjet

- Laser

- Percussion

Traceability

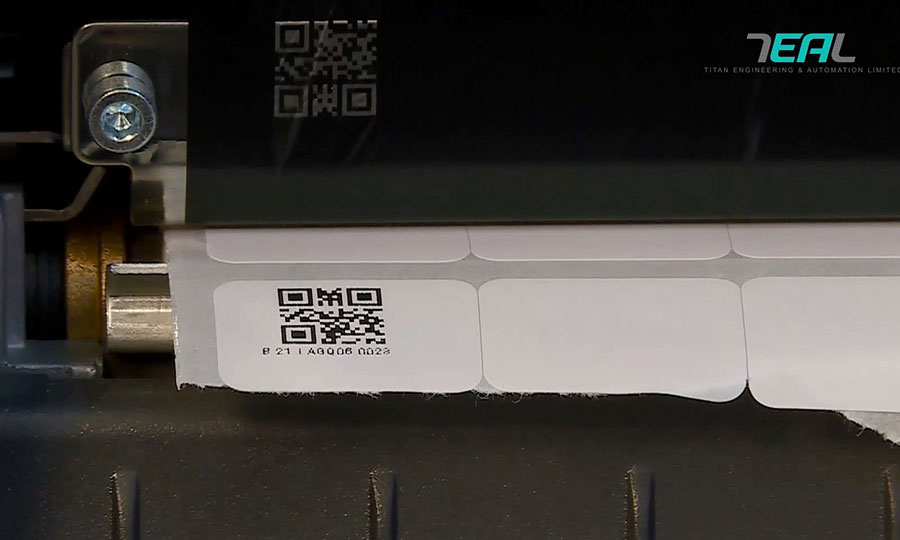

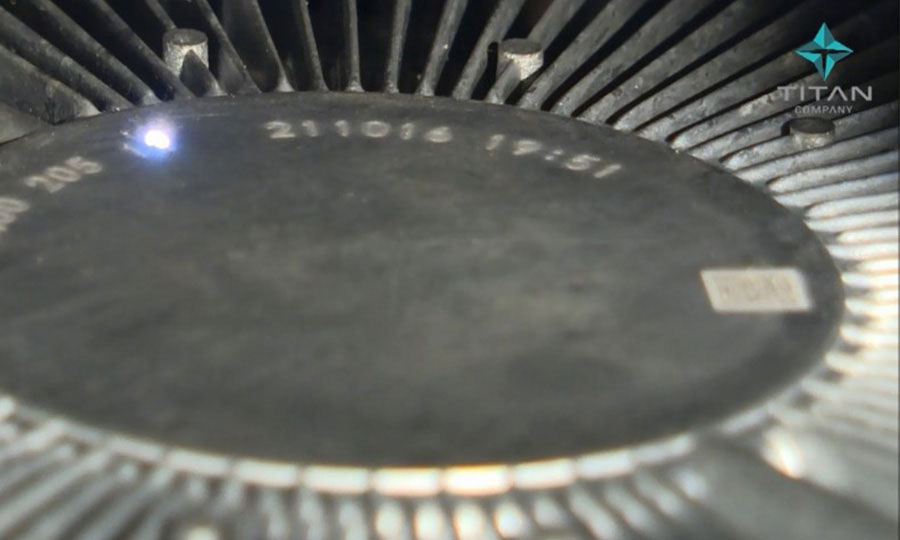

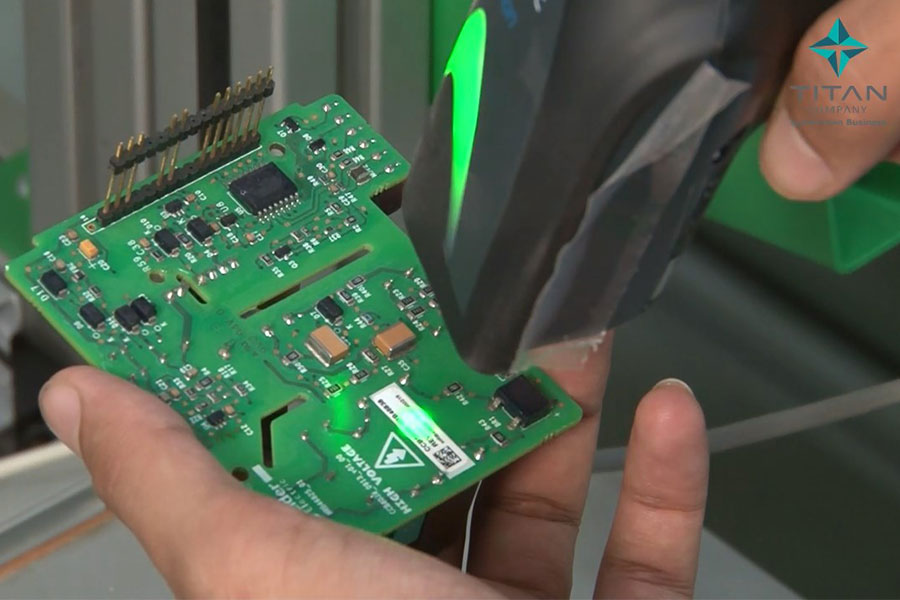

Traceability is very vital strategic tool for lifecycle management of any product. It gives manufacturers the much-required information on product performance, Quality, Warranty Data, Business Demands, etc.

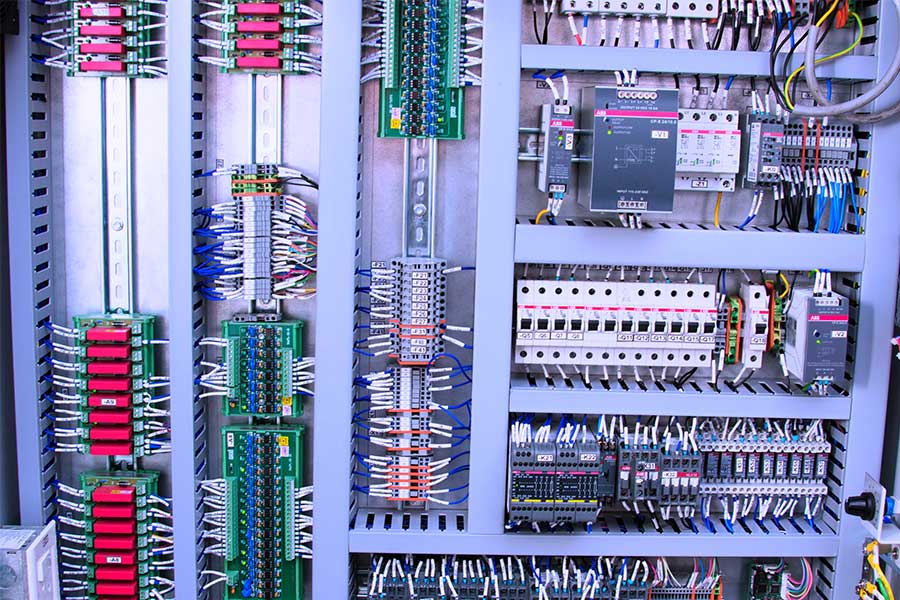

As part of the complete turnkey solution, we impart Traceability Systems in our assembly lines for capturing, storing, managing information automatically and also give Real-time information about production and machine. The final assembly will be Marked/Labeled for traceability. The distinct types of traceability systems include .

- RFID

- Barcode

- 2D Matrix

- Inkjet

- Laser

- Percussion

Traceability

Traceability is very vital strategic tool for lifecycle management of any product. It gives manufacturers the much-required information on product performance, Quality, Warranty Data, Business Demands, etc.

As part of the complete turnkey solution, we impart Traceability Systems in our assembly lines for capturing, storing, managing information automatically and also give Real-time information about production and machine. The final assembly will be Marked/Labeled for traceability. The distinct types of traceability systems include .

- RFID

- Barcode

- 2D Matrix